How to Save a Pig without Breaking the [Piggy] Bank

A Customer Story from In the Field

“Would you please tell me how you saved us a million dollars?” The unusual greeting was from Adam, a technology researcher at a major U.S. oil company.

by the team at GGS

January 17, 2017

“Would you please tell me how you saved us a million dollars?”

The unusual greeting was from Adam, a technology researcher at a major U.S. oil company. It’s not how all my phone conversations start, but it was a promising beginning.

Adam was reaching out to me because I had been on site at one of his company’s refineries the day before to find a cleaning pig that was stuck in one of their coker furnaces.

“How did you do it?” Adam asked again, and I began to recount the details.

I had received a call from the refinery’s manager asking if our Lixi Profiler, the tool we use for inspecting the condition of pipe, was capable of finding a pig in a pipe. I hadn’t used it for that purpose previously, but I figured it was worth a shot because of the Profiler’s unique ability to examine not only the condition of a pipe, but the pipe’s contents as well.

When I arrived at the plant, the manager was concerned. A stuck pig meant he had likely lost the ability to operate this division of the facility for at least two weeks. It would cost many man hours for crews to come in and cut the ends off every pipe segment in the furnace to locate the pig before welding the system back together.

I asked for a sample pipe and inserted a cleaning pig to find out if the Profiler could see where the pig was, but the pig was simply not dense enough to be measured.

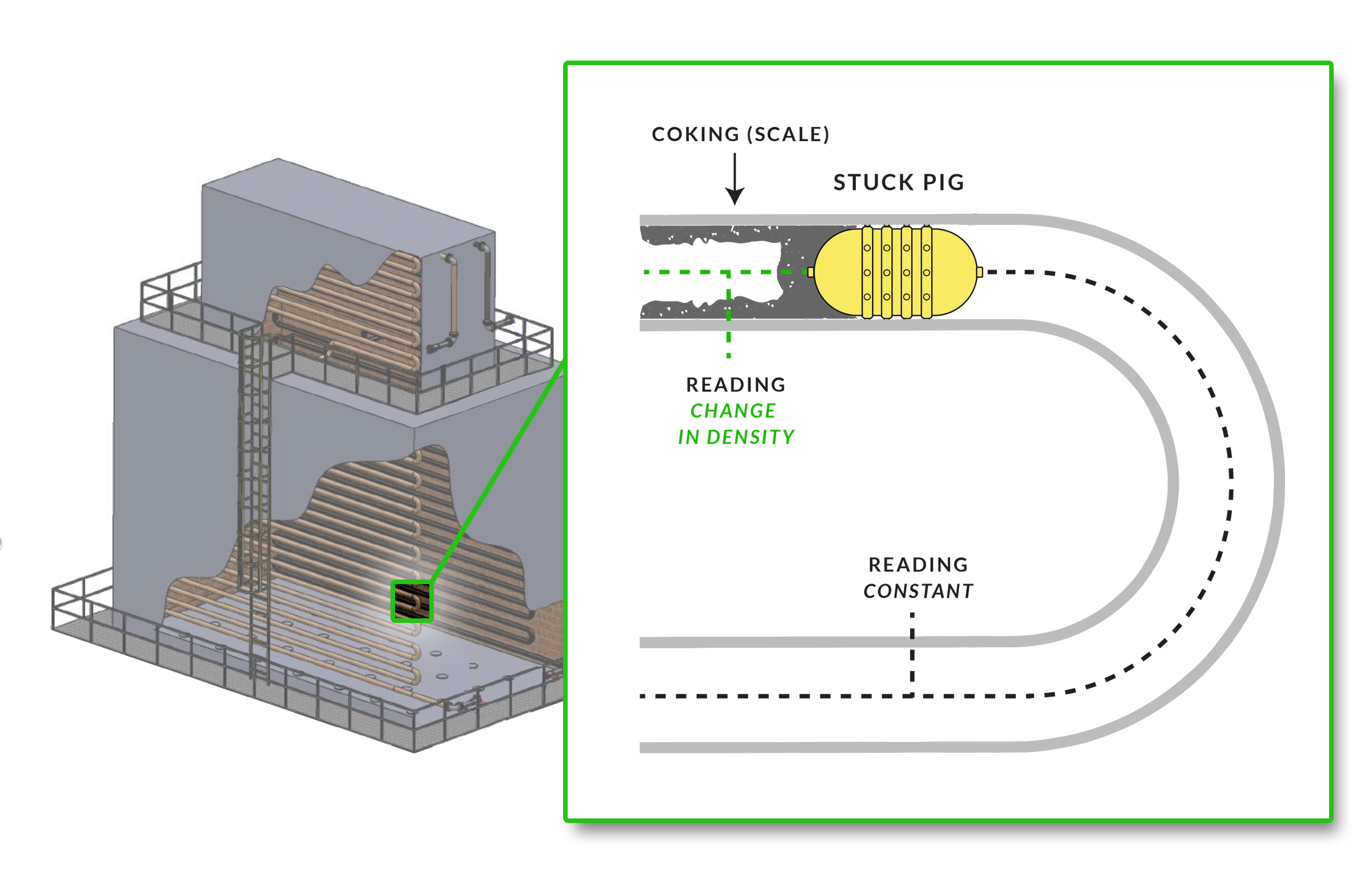

However, I knew that even if the Profiler could not determine exactly where the pig was in the sample pipe, it would be able to detect a change in density in the furnace pipe’s contents. Therefore, we should be able to identify the portion of the pipe that had been cleaned by the pig and also detect where there was a high concentration of residue still in the pipe—and where that contrast in density first appeared in the pipe should be where the pig was located.

My theory sounded reasonable to the plant manager, so he took me to the furnace and I began scanning the pipe with the Profiler. In just 20 minutes, I had passed the fourth return on the pipe—about 200 feet in length—and detected a major change in the density of the pipe’s contents. Past that point, the density varied widely, which made sense, since—if my calculations were correct—the pig had not reached those areas to clean the contents.

I was pretty confident we had identified the location of the pig, so the crew cut off the ends of that length of pipe. Out shot a bevy of coke that had become pressurized in the system, followed by the pig itself and a rush of water. The prodigal pig had come home without the need to cut, inspect, and weld hundreds of pipe segments.

The crew welded the two pipe ends together again, and the furnace was back in business after just a few hours. And to Adam, that represented over $1 million in savings.

I told Adam I could probably save him a few more dollars with the Profiler. Because of its ability to read the contents of the pipe—not being limited to spotting only corrosion—it could be used as a much more effective way to inspect the whole system of pipes to determine if it even needed to be cleaned, as well as how clean they are post-coking. In that case, his plant manager could know when to launch a pig instead waiting for a problem to occur or holding to an arbitrary schedule.

That type of intelligence, performed in such a quick manner, can’t be gained from traditional methods of testing and can be applied to numerous situations to find blockage or semi-blockage.

The Profiler was a new technology to Adam, and its speed and capabilities impressed him. But more than that, it represented a new approach to proactively looking for potential problems in pipe instead of reacting to an issue that has already compromised a system.