Our team was at a fossil power plant in Texas for a annual pipe testing with the LIXI Profiler.

As we walked through the plant, I stopped at a feedwater heater pipe that was about eight inches in diameter. This pipe was welded to an elbow, which was in turn, welded to the feedwater heater. The elbow had a Thickness Measurement Location (TML) installed for Ultrasonic Testing (UT), and I thought it would be a good opportunity to demonstrate the Profiler’s capability to the plant manager.

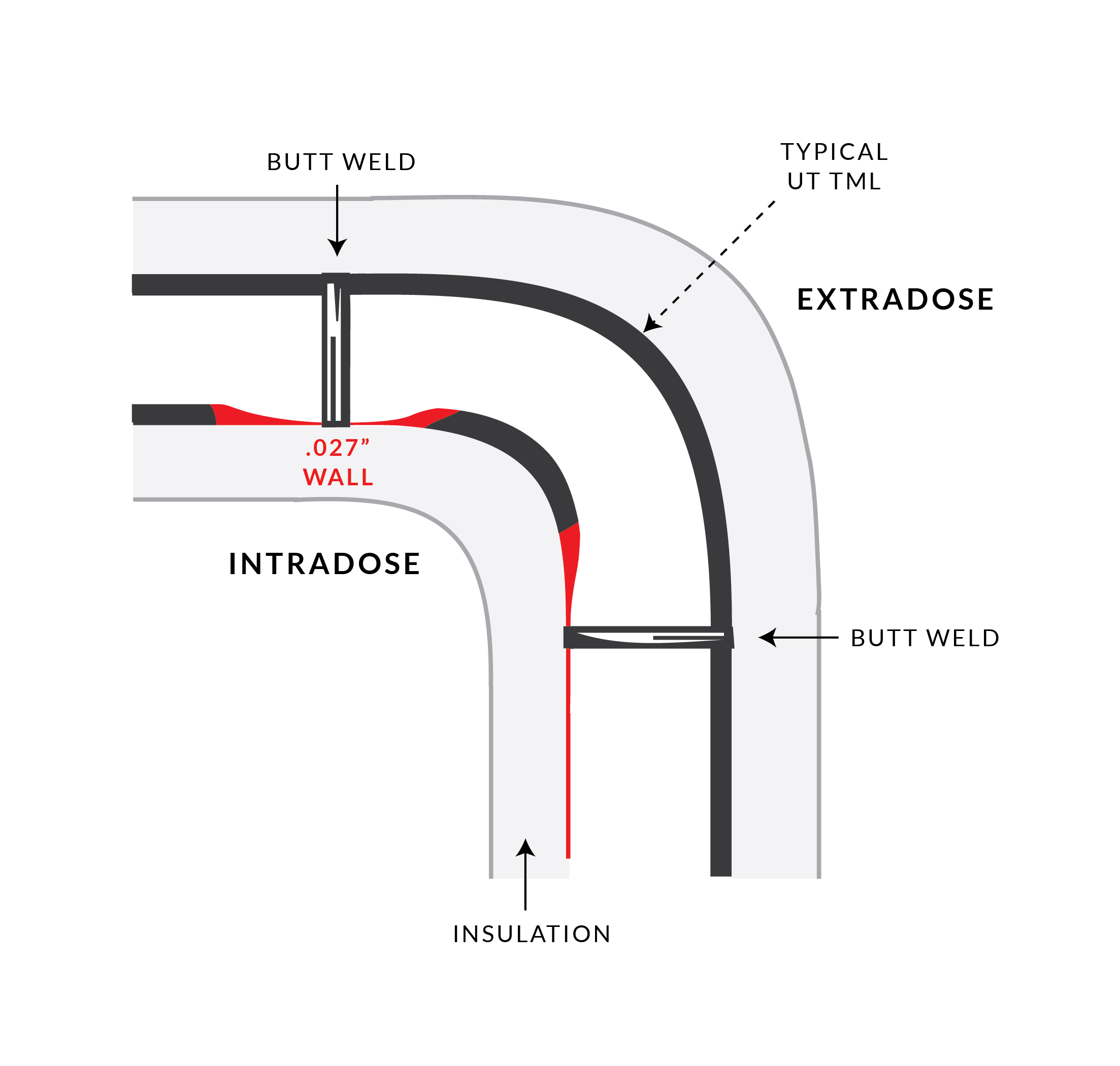

As with most elbow TMLs, this one was created by eyeballing the center of the extradose—the outer curve of the elbow’s arch—drilling a hole in the insulation, and monitoring the thickness of the pipe from that location. The center of the extradose is targeted because typically that is where erosion is expected to take place on the inside of the pipe. The built-in assumption is that by measuring the thickness of the pipe at that point, you will know when the pipe needs to be replaced. It is assumed that if there is enough thickness at that point, the integrity of the rest of the pipe should be sound.

I scanned the entire elbow in less than a minute and looked at the results. Meanwhile, the plant manager tried to persuade me that I was wasting my time with this part of the pipe.

“Don’t bother with that spot. We are already monitoring it and know it is losing some thickness, but it should be fine for a few more years,” he stated.

While he tried to convince me to move on, I reviewed the data the Profiler displayed. I noticed something unusual, prompting me to ask, “You do realize you are taking your measurement at the thickest point of the pipe, not the thinnest, right?”

We were perplexed. After all, they had been employing the industry standard method of testing at the time—positioning a TML in the place that would likely erode quickest, performing the UT, and estimating the remaining lifespan from there. It seemed safe to assume that if the TML measured to have satisfactory thickness, the rest of the pipe should as well.

But we were about to learn just how faulty that assumption was, because of the Profiler’s ability to detect issues – especially where they aren’t expected.

While UT was measuring the thickness of the pipe at the extradose, the Profiler scanned through the entire wall thickness (front to back or top to bottom) of the pipe—not only the extradose, but the intradose as well—the inner curve of the arch.

We compared the results of the ultrasonic testing to the numbers the Profiler generated for the extradose of the elbow, and both indicated the pipe had plenty of thickness in that area. Therefore, I knew the intradose must be the part experiencing significant erosion.

The Plant Manager playfully questioned whether I knew what I was doing using the Profiler, as it didn’t make sense to him that the intradose of the pipe would be eroding at a much faster rate than the extradose.

So I applied UT to the intradose of the pipe to see if it would confirm what the Profiler was telling me.

“What are you doing?” he asked. “It never erodes there.”

Sure enough, a large area on the intradose of the pipe that was supposed to be .325” had eroded down to .027”—paper thin.

Sure enough, a large area on the intradose of the pipe that was supposed to be .325” had eroded down to .027”—paper thin.

This caused even further consternation for the plant manager, who now was wondering if I knew how to use both the Profiler and the UT system.

It was time to prove that the Profiler’s results were accurate. I told him he could kick me out of his plant if I was wrong, so he brought out his welder and cut out the elbow. Sure enough, that pipe was incredibly thin at the intradose, yet had only mild erosion at the extradose.

Changing his tone, he exclaimed, “That would have failed on startup!”

Fortunately, the Profiler prevented an unscheduled shut down, and possibly even saved his job.

The Profiler had quickly and easily alerted us to a problem we otherwise never would have detected. The built-in estimation and assumptions of the UT process only look at one portion of the elbow.

What caused this elbow to erode in a manner the Plant Manager didn’t expect?

There is a deflection plate in the feedwater heater that causes the water to enter the elbow in a straight line, but the plate had broken off. So instead, the flow was entering at an angle and swirling within the pipe, creating a different erosion pattern. Over the years, we have found that this is a surprisingly common issue.

While many plants continue measuring elbows at the extradose—sometimes even at multiple points throughout the elbow exterior—they are still operating on assumptions that may be faulty. But more importantly, the Profiler provides the ability to overcome those assumptions quickly and easily, without having to cut more holes in the insulation to create additional TMLs. Instead, it precisely measures the entirety of the pipe for defects, side-stepping pre-existing notions for a true representation of the integrity of a section of pipe.

You may also have issues where you don’t realize it. In the case described above, we found erosion not only on the elbow, but on an additional four feet of pipe. It hadn’t been tested previously, because no one expected to find erosion there.

Once the Plant Manager saw how the Profiler revealed the issues within that pipe, he asked us to use it to look for issues throughout his plant.

It was time to throw out conventional assumptions and bring in the Profiler.