Technology

Radiometric Profiling for Piping Ultrasonic Thickness for Vessels Compare Common NDT Methods

Ultrasonic Thickness Testing (UTT)

GGS evaluates pressure vessels with Ultrasonic Thickness Testing to reliably find and measure every condition necessary to manage operational health and safety of insulated and uninsulated pressure vessels.

UTT is one of the more common NDT techniques due to ease-of-use. Ultrasonic thickness testing measures the wall thickness of a properly prepared sample (pipe) by touching the transducer to the surface of the pipe.

This method is very good at measuring the thickness of a single-layer sample – optimally, a clean, flat, sample at moderate temperature.

For all measurement locations, insulation needs to be removed so the transducer comes into direct contact with the bare pipe.

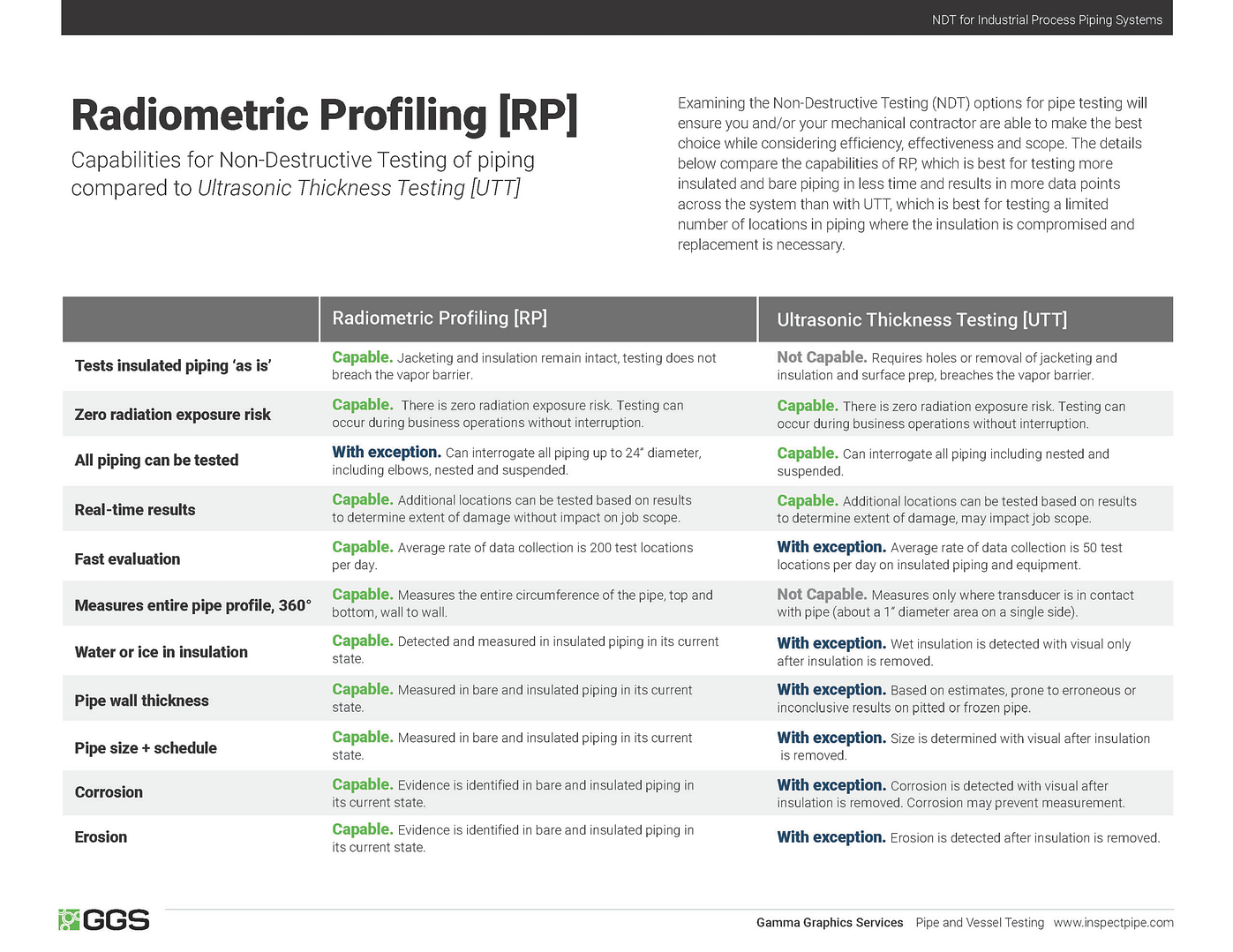

When determining the best method for your industry and company requirements, there are many factors that should be evaluated. Examine the following characteristics of ultrasonic thickness testing on piping.

Characteristics of UTT

- There is no risk of radiation with UTT, it is 100% safe to resume operations while testing.

- Measures corrosion and wall thickness.

- Can evaluate all vessels and piping – nested and suspended.

- Technicians can test up to 50 locations per day with UTT.

- UTT is able to provide real-time results.

Limitations

- Requires removal of insulation.

- Requires surface preparation at testing location.

- Measures only where transducer is in contact with pipe (about a 1” diameter area on a single side).

- Measurements are prone to erroneous results on pitted or freezing pipe, and require built-in assumptions.

Consider a better method for testing your piping.

Ultrasonic Thickness Testing (UTT) can be used for testing a limited number of locations where the piping is not insulated or the insulation is compromised and replacement is already necessary.

Compare an alternative that doesn’t require you to settle. Radiometric Profiling (RP) tests 4 times the number of locations in a single day and doesn’t require removal of insulation.